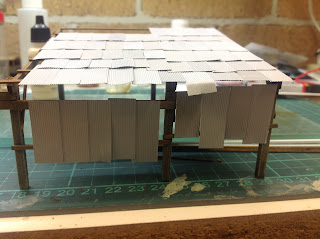

A little bit of progress on the facilities for Splitters. I've wanted to start this for a while. As I've said many times I enjoy working with timber and this project was a simple one to do on the workbench.

The Data Sheet available from Greg Edwards has two different types of stage and the 1900 one is the perfect one for my layout. There are a few different timber sizes, but basically the structure is the same for each design.

I began with prestaining all the timber so that I didn't have to worry about trying to stain after gluing it up. I also prefer doing it first so that when it is built there are different colours to the timber that doing it after construction would be difficult to achieve.

I cut up all the decking timber first and had a pile to use. By laying all the decking down first I built this part from the deck down. So the bearers were glued on top of the decking timber and set aside to dry.

Next up were the sides of the coal stage, one whole side and the other with a gap wide enough for a D wagon. This is one of the main differences between the two designs on the sheet was that the later design had a gap fitting much longer wagons, whereas the early ones were specifically for the shorter four wheeled D wagon.

I then simply glued the sides on and allowed it to dry. Then cut up the timber for the ends and installed them.

To help with holding the sides in place the universal jig, bluetac was put in place.

Once this had all dried out I did some light weathering on top of the deck to show some change in colour of the timber.

This photo shows up the variation in the deck before the addition of coal.

I've pre drilled holes in the timber uprights to hold the bolt detail, and they are being weathered as I write this.

Next up the base of the stage and there is a bit of cutting and sanding involved. So I'll leave it there for this post.

Have a great week!

Oorroo!

Geoff.